Supply lead time, financial figures, and employee autonomy: utilizing DX for three-fold reform through supply chain visualization and short-cycle operations

BPR leader:

Tetsuya Tajima

Chief Time-Value Officer and Operations Head

i-PRO’s time-based competition refers to the construction of operational excellence in the following two fields. The first is the engineering chain, that is, product development lead time; and the other is the supply chain, that is manufacturing and logistics lead time. Through this, we supply customers with the latest technology quicker than other companies, valuing the time of our customers by realizing prompt delivery through an optimized supply chain.

Our operations management team is manifesting time-based competition by simultaneously realizing two competing factors:

- Order-processing, shipment, and logistics operations to deliver products required by customers at the required time and in just the required amount

- Inventory management operations to maintain appropriate inventory levels and cash conversion cycle

The challenge of achieving both of the above is increasing each year due to the changeable nature of external conditions and growing uncertainties affecting procurement of semiconductor parts and international transportation capacity, etc., in addition to customer needs. We have implemented various reforms to achieve this.

■DX reforms aimed at realizing optimized overall management

i-PRO implements its business mainly through its two factories and four sales offices (Japan, Americas, EMEA and APAC).

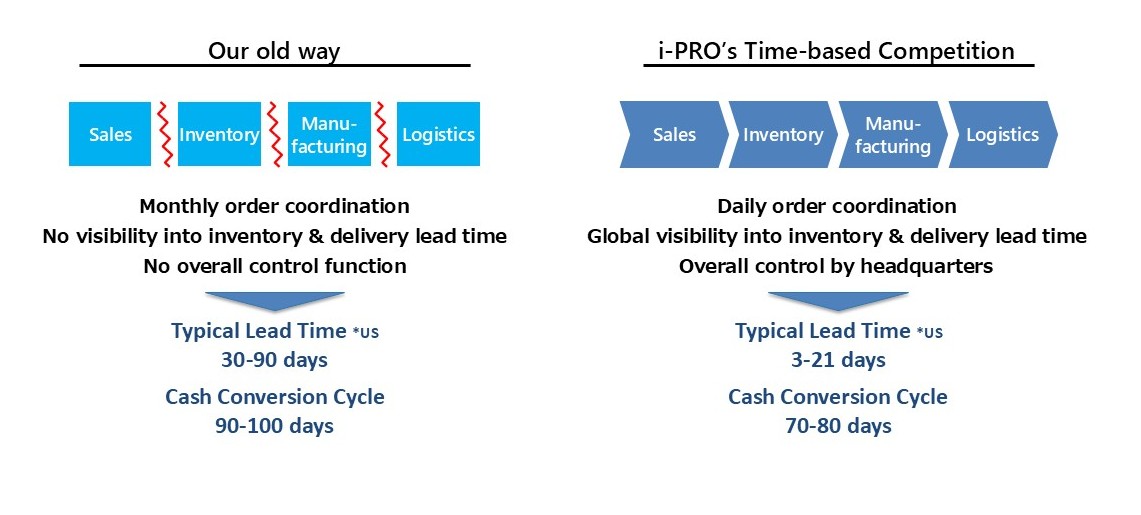

Prior to i-PRO becoming an independent company in 2019, we had no overall control function. Information coordination between sales offices and factories was conducted on a large-batch monthly cycle (confirmed three-months in advance). Also, we had no visibility of our global inventory and delivery situations. Connections between divisions and functions were weak, and consequently, demand and supply were not synchronized. We fell into a negative spiral, with long delivery lead times and lost sales opportunities resulting in high inventory levels, a worsening cash conversion cycle, and lower employee motivation due to increased emergency response.

Since becoming independent, we have aimed at realizing visualization for optimized overall management, as well as cycle-shortening through information coordination. Our independence provided opportunities to introduce globally integrated key systems and DWH (Power BI*), whereby we realized cross-sectional visualization of order-processing, delivery, and inventory information for all sales offices and factories. This was the starting point of overall control by headquarters, advancing setting of supply and delivery targets and overall global optimal inventory deployment levels, along with daily order-processing operations coordination based on actual demand. In addition, through cross-sectional visualization, the work scope of representatives has expanded, and we have switched personnel placement from function-based (e.g., order-processing handlers and shipment handlers) to sales region-based, significantly increasing the discretionary power of team members.

This has resulted in the birth of a positive cycle of short supply lead time and reduction in lost sales opportunities, helping to reduce inventory levels, improve our cash conversion cycle, and boost employee autonomy. In the U.S., for example, we shortened our typical lead time of 30-90 days to the current level of 3-21 days, and our overall cash conversion cycle of 90-100 days down to 70-80 days.

■More seamless global end-to-end operations coordination aimed at the next stage of our growth

Presently, we are undertaking expansion of information coordination aimed at the next stage in our evolution. We will further expand end-to-end supply chain information coordination, covering sales pipelines, sales partner order-processing and inventory, and also transportation tracking, aimed at achieving seamless operations.

In this way, we hope to provide customers with a supply chain that values their time even more, thereby contributing to the growth of our customers and of i-PRO.

*Power BI is a business intelligence (BI) tool offered by Microsoft Corporation.